Custom Rubber Products Manufacturer

Saga Elastomer is an ISO 9001:2015 accredited company having a working culture that is highly systematic and process oriented. A highly sophisticated plant with latest machinery, equipment, testing facilities, an experienced & well-trained team, perfectly documented processes and traceable product tools & batches form the very backbone of our systems.

Our customers vouch for our passion for precision, inclination for innovation and moreover, with the humility that we do our business. Our customers have highest regards for our values, ethics, knowledge and capabilities and hence have been with us for longer period of time.

When you chose Saga, you know all your demands will be fulfilled with utmost care, superior quality, precision, meeting your timelines and most importantly, maintaining transparency & communication.

Our Primary services

Saga Elastomer specializes in the manufacturing of extruded and moulded rubber products, ensuring they meet the highest international standards.

Our infrastructure:

Our state-of-the-art infrastructure boasts 2 continuous vulcanizing machines, 3 conventional extruders, and 1 autoclave with 6.5-meter lenght for high-volume, consistent production. We also have 5 compression molding machines, a splice jointing machine, 2 kneaders, 2 mixing mills, and quality control equipment like rheometer and semi automatic weighing machineto ensure intricate designs, precise material handling, and consistent product quality.

The kind of customers who love our work are the ones who appreciate consistency of product quality, timeliness of delivery and working with them transparently on their requirements.

We are passionate about

process and precision.

We deliver products with your stringent

quality norms.

We follow strict timelines,

every time.

Integrated partner in your

progress and success.

We collaborate & accommodate your

last minute changes.

Bespoke product development and

embrace changing technology.

Enhancing experience by clear and

timely communication.

Building long lasting relationships

with our clients.

Worldwide presence

Updates

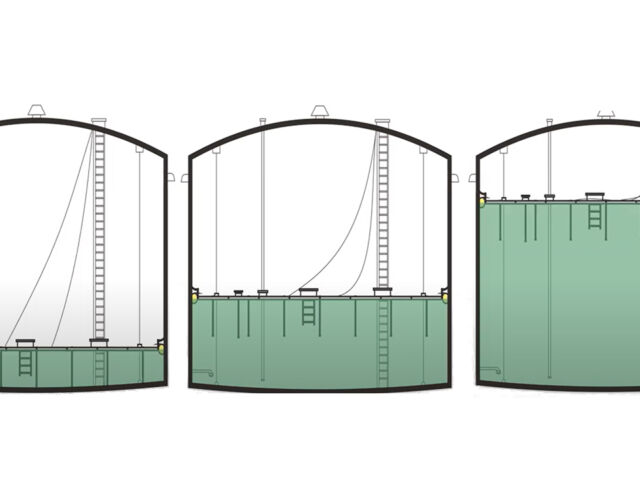

Why do some floating roof tanks outperform others?

The secret often lies in the abrasion resistance of their seals

Bringing the warmth of Diwali to our workspace! Team Saga celebrated with festive joy, lighting up the office and our spirits. Wishing everyone happiness, success, and new beginnings this Diwali!

Neoprene Vent Bands are used in most diversified mining applications like for heavy equipment housings, the enclosures of engines, and conveyor belts, ventilation vents. They make a snug seal keeping out dust, water, and other kinds of particles that may leak into the machinery and malfunction it.

News

We are delighted to share the December’23 edition of Industry Outlook Magazine featuring your trusted partner in driving innovations in bespoke rubber manufacturing, Saga Elastomer Pvt Ltd!

We are thrilled to share that Saga had the pleasure of hosting esteemed international customers at our plant. It was an incredible opportunity for us to showcase our commitment to global partnerships and deliver exceptional experiences to our valued guests.

Our Chairman Mr. M J Laddha is now 80years young. He is the epitome and live example of the statement “Age is just a Number”. He has been actively involved not just in strategic planning but also day to day operations. He is a guiding force behind the positive changes Team Saga has seen in last couple of years