Are you a glass facade manufacturer who is seeking to ensure structural integrity and enhance the security of your projects? We understand the challenges you face in creating safe and durable glass facades that withstand environmental factors and potential risks.

Maintaining consistent quality and durability of rubber components is crucial for glass facade manufacturers. Rubber materials should be able to withstand long-term exposure to environmental elements, including sunlight, heat, cold, moisture, and chemicals. Ensuring that the rubber components maintain their sealing and insulation properties over time is essential for the longevity and performance of the glass facades. In this blog, we will explore the importance of architectural profiles in achieving structural integrity for secure glass facades.

The Challenge for Glass Facade Manufacturers

Glass facades are increasingly popular in modern architectural design, offering transparency, aesthetics, and natural light. However, ensuring structural integrity and security is a critical concern. Without proper support and reinforcement, glass facades can be susceptible to external forces such as wind pressure, temperature changes, and impact risks. As a glass facade manufacturer, you understand the importance of finding reliable solutions that address these challenges and deliver long-lasting performance.

When structural integrity is compromised, concerns arise about the safety of occupants and the reputation of the project. The fear of glass breakage, instability, or inadequate support can lead to doubts and hesitations among architects, developers, and clients. Meeting stringent building codes and regulations becomes imperative to ensure compliance and prevent potential liabilities. It’s essential to find a solution that instills confidence, offers durability, and provides peace of mind.

A Solution for Structural Integrity

At Saga, we have invested significant time and energy in developing high-quality architectural profiles specifically designed for glass facades. Our goal was to provide glass facade manufacturers with reliable solutions that address the challenges of achieving structural integrity and security. Through extensive research and adherence to the highest quality parameters, we discovered a solution that meets the stringent requirements of the construction industry.

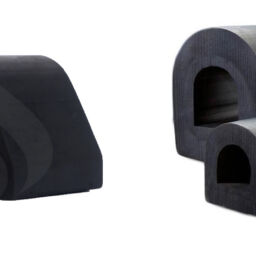

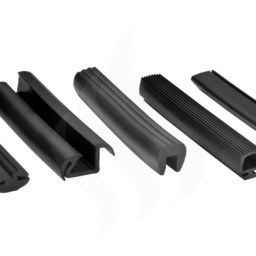

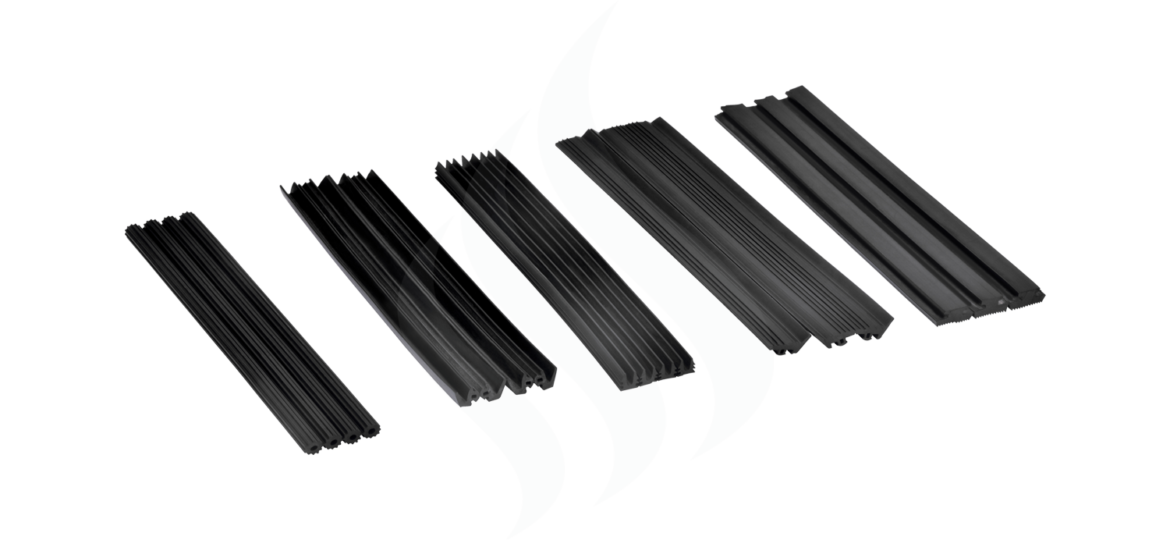

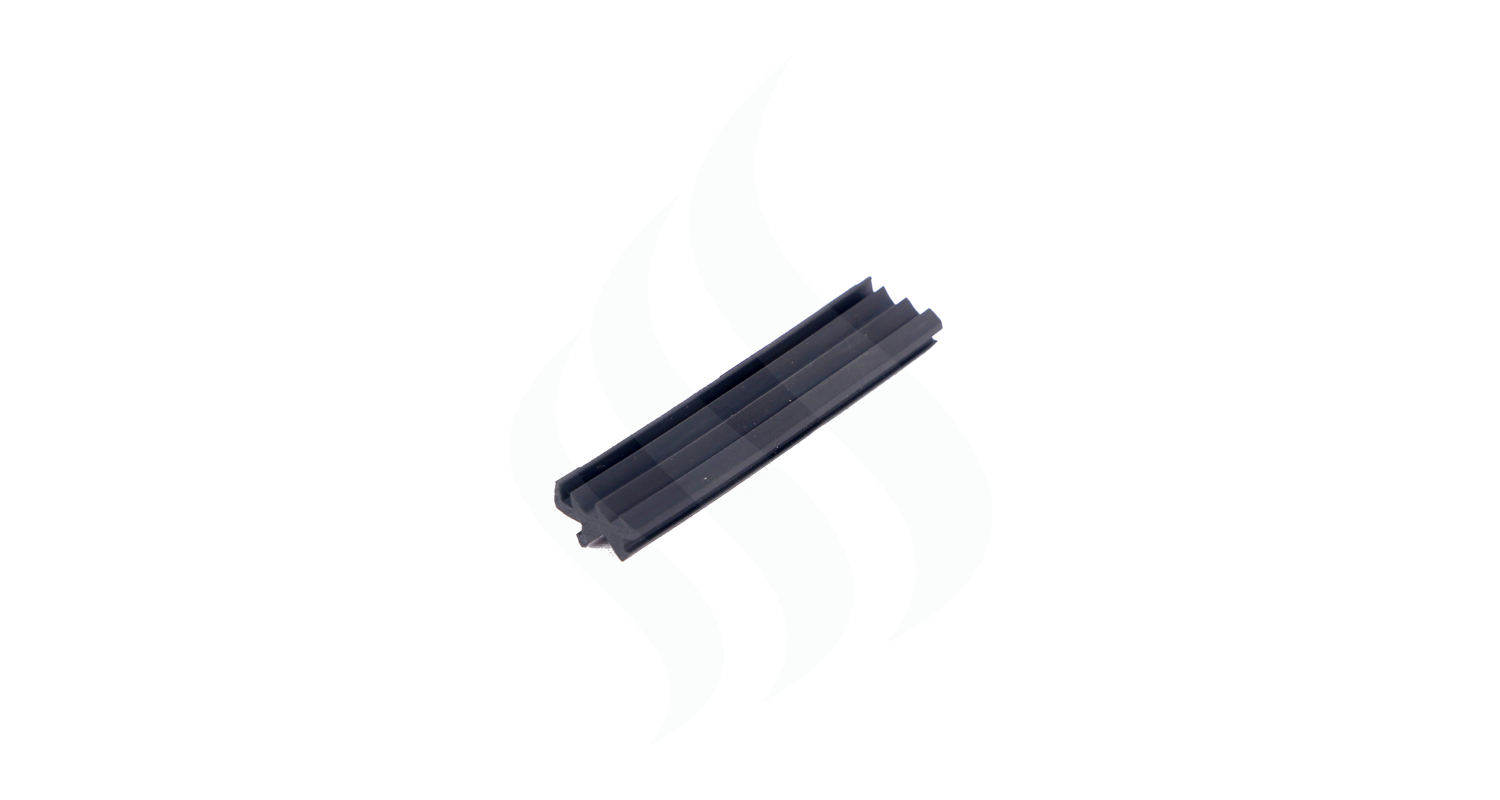

Saga Architectural Rubber Profiles: Tailored to Your Unique Project Needs

Saga offers a wide range of architectural profiles for glass facades, including EPDM rubber profiles and silicone profiles that deliver exceptional performance and ensure structural integrity. Our EPDM rubber profiles are renowned for their ease of installation, high strength, and durability, resulting in low replacement hassles. These profiles effectively hold the glass and aluminum sash, acting as shock absorbers to withstand external forces. With superior sealing properties, our profiles contribute to soundproofing, ensuring a quiet and comfortable environment. Additionally, we manufacture silicone profiles for architectural requirements, providing further options to meet your specific project needs.

One of the key advantages of Saga architectural profiles is their resistance to humidity and temperature variations, even in adverse climatic conditions. This ensures long-lasting performance and prevents material degradation over time. Our profiles possess excellent anti-aging properties, maintaining their integrity and aesthetic appearance for years to come.

We acknowledge that every project is unique, which is why we offer a wide range of models and sizes to cater to diverse design requirements. Additionally, our customization options allow you to tailor the profiles to your specific project needs, ensuring a perfect fit and seamless integration.

At Saga, we understand the importance of meeting industry standards and specifications. Our architectural rubber profiles are manufactured with strict adherence to the relevant standards to ensure compliance and performance as mentioned below.

| Standards | Parameters |

| ISO 9001:2015 | Quality Management System |

| ASTM D-297 & ASTM E-1131 | Polymer Content, Ash Content & Density |

| ASTM D-412 | Tensile Strength & Elongation at Break |

| ASTM D-2240 | Hardness |

| ASTM D-573 | Change in Physical Properties Like Tensile Strength, Elongation at Break & Hardness |

| ASTM D-295 | Compression Set |

Key Considerations for Architectural Rubber Profiles

- Design & Engineering Complexity: Achieving a balance between functionality, aesthetics, and performance can be challenging. Rubber elements such as gaskets, seals, and profiles need to be accurately designed and integrated to provide effective sealing, thermal insulation, structural support, and water resistance.

- Thermal Expansion & Contraction: Glass and rubber have different coefficients of thermal expansion. The architectural profiles should accommodate these differences to prevent stress on the glass and ensure long-term performance.

- Weatherability Properties: Architectural profiles should possess excellent weatherability properties, withstanding UV radiation, extreme temperatures, and moisture without degradation. This ensures the durability and reliability of the glass facades in various climatic conditions.

- Water & Air Tightness: Effective sealing is crucial to prevent water infiltration and air leakage. Architectural profiles should provide a reliable barrier against water and air, ensuring the comfort and energy efficiency of the building.

- Durability: Our architectural profiles are designed to withstand long-term exposure to environmental elements, providing lasting performance and minimizing the need for replacement.

- Maintaining Consistent Quality: Consistency in quality is a paramount consideration when it comes to architectural rubber profiles for glass facades. To achieve and maintain consistent quality, Saga has implemented rigorous quality control measures at every stage of the manufacturing process. From material sourcing to final inspection, we adhere to strict standards and procedures to ensure that our architectural rubber profiles meet the highest quality requirements.

- Precision & Customization: We understand that every project is unique. Ensuring precise dimensions, accurate tolerances, and high-quality finishes for rubber profiles can be challenging. At Saga, we have proper control over manufacturing processes, including material selection, curing, vulcanization, and surface treatments, to ensure that our rubber components meet the required standards and specifications. Customization options are available to tailor the profiles to your specific project needs, ensuring a perfect fit and seamless integration.

Partner with Saga for Secure Glass Facades

To achieve structural integrity and enhance the security of your glass facades, partner with Saga. Our architectural profiles for glass facades, including EPDM rubber profiles and silicone profiles, are trusted by leading names in the construction industry for their consistent quality, durability, and reliable sealing properties. By choosing Saga, you benefit from our precision focus on dimensions, customization options, and adherence to the highest quality parameters.

If you found this blog insightful, we encourage you to share it with your colleagues and connections. Should you have any questions or require further information about our architectural profiles for glass facades, feel free to drop us a message. Together, let’s create secure and remarkable glass facades that stand the test of time.