At Saga Elastomers, we are on a mission to tackle on industry challenges and deliver solutions that go beyond customer expectations. This is how Team Saga advanced solar gaskets solved critical issues for one Indian solar project, ensuring durability and performance for those installations.

Starting Out – An Inquiry

On one sunny day, Team Saga, got a call from a reputed player in India’s solar sector. They had a problem at their latest solar farm and they urgently needed help to fix it. Their project coordinator laid out the issues that they had:

- Water infiltration into the panels

- More panel vibration

- Increasing maintenance costs

It was clear that they needed a timely and effective resolution to ensure the continuity andefficiency of their solar installations.

Problem Analysis

Soon after having a call from one of our clients, we narrowed down to the problems that they raised up. Those situations were the ones that were infringing on the effectiveness and the life of the solar panels.

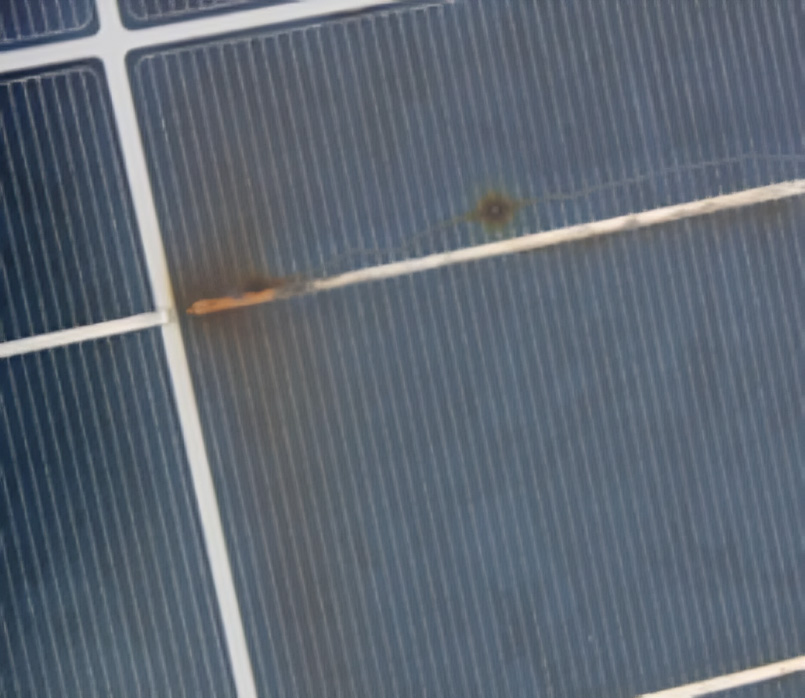

- Water Seepage and Corrosion:

The client told us about a big problem with water getting into the solar panels. This caused rust and damage. Poor sealing let moisture get in and hurt the parts inside. Water made the panels work worse and could mess up their electrical systems over time. - Wind-Induced Vibration:

The solar farm sits in a very windy spot, which shakes the panels a lot. When the shaking is constant, there is a possibility that the panels will break and might be more prone to get damaged. More so, the shaking can loosen parts and make the panels get knocked out of line, which will cause them to work even worse. - High Maintenance Costs:

Because of water leakage and wind damage issues, the costs for maintenance that can be considered as a normal routine maintenance, were rather high which made it rather challenging to maintain the state of the home as needed in a regular basis. Surveys became frequent, and the responsibility of repair work came on the client, which had a great impact on the cost of operations and thus exerting a greater strain on the business resources. This sort could not have lasted and was seeking a dependable way to decrease the number of times it is corrected and its cost.

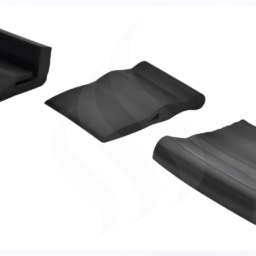

After careful reviewing and discussion with the team, we proposed the installation of Sagaseal® Solar Panel gaskets. These were developed to handle exact issues that the client raised. Development and implementation of these gaskets followed a process to ensure they perfectly fit into the requirements.

- Customization to Gap Dimensions:

Our team took a close look at the client’s solar panels to get the exact measurements and details. We then designed the gasket to match these specific gap sizes. This custom approach was key to make sure the gasket fit and sealed.

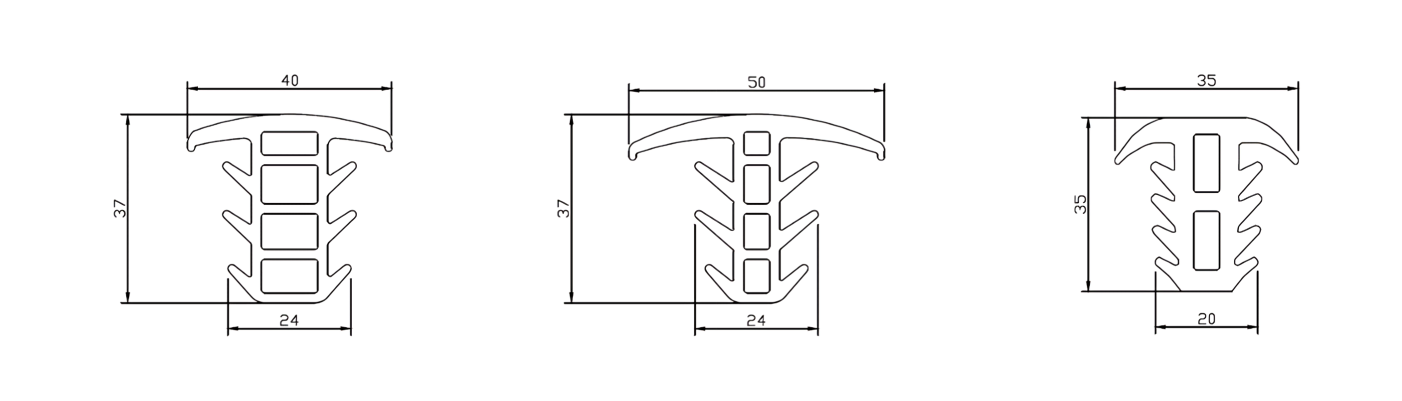

- Development of Technical Drawings:

We initiated this project by developing comprehensive technical drawings of the proposed gasket design. The drawings indicated specifications and materials to be used, setting out all information in crystal-clear precision. The said drawing was reviewed and approved by the client for the green light to proceed. - Tool Development:

With the design finalized, our skilled engineers got to work, crafting a specialized tool to produce the essential gaskets. This custom-made tool ensured that each piece met the project’s requried quality standards, achieving the precise tolerances and consistency required. It was a crucial step in bringing this project to life. - Pilot Lot and Client Approval:

Before mass production, we crafted a sample batch of the Sagaseal® gaskets. This initial set was sent to the client for evaluation and testing. The sample performed exceptionally well, addressing key issues like water seepage and wind vibration. The client was thrilled with the results and approved it. - Major Order and Full-Scale Implementation:

After a successful trial, the client placed a substantial order for our Sagaseal® gaskets. Our team swiftly ramped up production and collaborated with the client’s technicians to ensure a seamless installation across the entire solar farm. It was a smooth and efficient process all around.

Implementation and Results

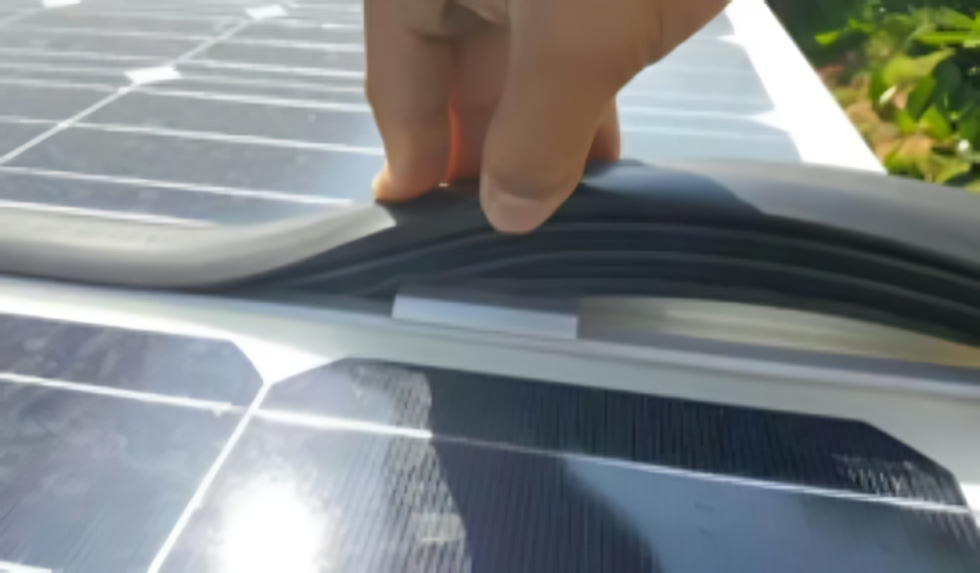

Our team worked closely with the client’s technicians to install the new gaskets across the entire solar farm. The process was smooth because of the ease of installation and flexibility of our gasket design.

The results were immediate and impressive. The water leakage issue was completely resolved, with no further incidents of corrosion. The vibration from strong winds was drastically reduced, stabilizing the panels and preserving their structural integrity. Maintenance requirements dropped significantly, saving the client both time and money. Moreover, the gasket’s ability to handle temperature fluctuations ensured that the panels continued to perform optimally, regardless of the weather conditions.

Conclusion

This case study demonstrates Team Saga dedication to addressing industry-specific difficulties with innovative solutions. Our advanced solar gaskets have proven to be a game-changer, providing reliable protection and enhancing the performance of solar installations. At Saga, we continue to push the boundaries of what’s possible, always striving to exceed customer expectations. If your solar projects are facing similar challenges, let us help you find the perfect solution. Reach out to Team Saga today, and let’s work together to power a brighter future.

Related product: Solar Rubber Panel Gasket