Are You Losing More Than You Think?

Storage tank vapor loss can drain your operations. Even tiny leaks build up to big product losses over time. Picture thousands of litre of your precious product vanishing into the air just because your tank wasn’t sealed. Studies show that a single tank with poor sealing can lead to yearly losses worth thousands of dollars in product.

Consider this: Your tanks sit outside all day, every day facing harsh weather. These conditions all play a part in slow vapor leakage through changing temperatures, pressure shifts, and daily wear and tear. While this might seem minor at first over a few days or weeks, these amounts can grow huge over a year. Every litre of product that escapes into the air represents a missed chance, whether it’s fuel you could have sold chemical resources you could have used, or something else.

Additionally, uncontrolled vapor emissions are another reason for environmental pollution. Together these may impair nearby ecosystems and surroundings. It not only creates legal risks for your company but also is your reputation as a social actor in danger.

So, what’s the real cost of vapour loss?

Busted product is not the only thing because lost income, possible fines, more difficulties with regulators, and bad reputability are also possible.

The good thing is that you can prevent all of these by spending some money on the sealing of floating roof tanks in the right place.

The Smart Investment for Efficient Tank

Secondary seals are the solution to the problems and they ensure not only the safety but also high productivity and durability of the storage tanks. They set aside the process of the vapor escape by layering the emissions with a barricade that guards your treasures.

Reasons for extra seals in your business are outlined in the following list:

1. Reduce Product Loss:

Every drop counts. This is evident in heavy industries handling volatile compounds like gasoline, diesel, and chemicals. These products evanesce through vapor as they stay in the tanks for some time with no sealing and that leads to the great products’ losses. Secondary seals are the most convenient method of resolving this vapor leakage problem by providing additional cover for the product and keeping it in place.

2. Enhance Safety:

Control of safety is one of the most important key factors in every production process in industries with special reference to those industries that are managed with hazardous materials. With regard to Hazards, while venting alone presents an environmental menace, it also makes the working environment hazardous. Release of vapours may result in build-up of explosive charges and enhancing the prospects of fires, blasts, and other disasters. These secondary seals effectively prevent these toxic vapours from escaping hence greatly lowering the incidence of harm. In addition to making your tanks safer for your employees, secondary seals also offer protection to the company’s investments – it is a win-win situation.

3. Lower Maintenance Costs:

By having the tanks well sealed, less maintenance is needed than when tanks are at a high risk of developing leaks. More so, if you do not have secondary seals, your tanks will constantly be worn down by the escaped vapours and prevailing environmental conditions. This results in more constant unscheduled maintenance, higher expense of repairs and more time off. Secondary seals eliminate these effects because they maintain the condition of your tanks, infrequent overhaul, and the endurance of the equipment is achieved.

4. Protect the Environment:

Sustainability is not only an issue of compliance with the law, it’s an issue of compliance with business. In terms of the protection of the environment, secondary seals are useful in stopping the emission of dangerous vapour that is bad for the environment hence making your company green, environmentally friendly. Whether it is a reduction of Greenhouse Gases or the prevention of hazardous chemical spills, secondary seals allow you to protect the environment.

We appreciate that your production requires dependable sealing solutions. At Saga, we provide second generation seals that excel in the protection of your storage tanks, your business, and the environment.

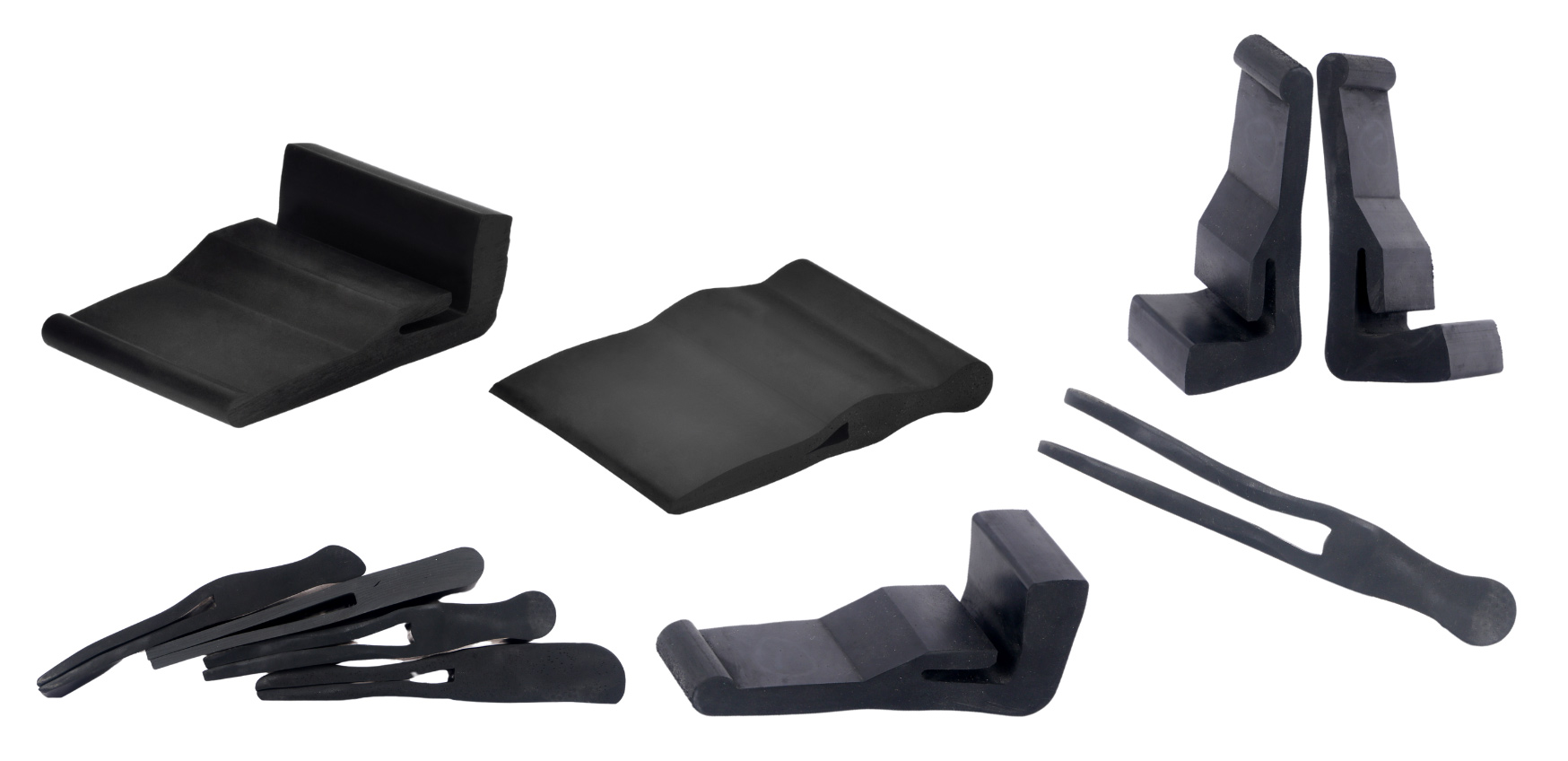

SagaSeal Floating Roof Tank is a secondary seal that helps to define the space between the floating roof and the tank shell so that it might help in minimizing the evasion of the lighter vapor. The key specifications of our products:

- High Tensile Strength: Claims which assert that the seals perform effectively at high temperature, pressure, and cycling without any adverse effect of such conditions.

- Excellent Abrasion Resistance: Provides the needed measures of abrasiveness and hardness bearings in mind it has to possess the right weight and flexibility that can affect positioning of the product at hand negatively.

- Vapour-Tight Splicing Options: Makes sure that there is interaction between the outer skirt and the seal touching the tank diameter to prevent development of any vapour leakage.

- Length Options: Seals can be made with a maximum length of 25 meters so as to minimize joints in the sealing system hence minimize leak points.

- Wide Range Availability: here are many options of the seals, which may be applicable for peculiar kind of tanks and/or working conditions.

- Customization Options: The operation can obtain tailor-made solutions that will be appropriate for your business operation.

This seal is employed as the second mean of sealing in internal floating roof tanks (IFRT). These wiper tips are made specifically to eliminate unproductive product loss as well as internal floating roof tanks (IFRT) contamination by atmosphere. SagaSeal are designed to work optimally where the tank’s condition will be optimal for its function. Saga offers many different IFRT wiper tip seals and is happy to produce them in any way you would like to receive for your tank.

Not ready to guard your resources and revenues? Contact us now to learn how our secondary seal solutions can benefit your business.