Avoid facade seal failure. Explore expert tips on UV-resistant elastomeric sealants for glass buildings. Get practical advice that actually works!

Introduction

Glass facades bring in sunlight, create stunning exteriors, and make buildings look sharp and modern. But over time, there’s a hidden enemy working against all that beauty—UV rays.

If you’re a façade designer, contractor, or someone dealing with high-rise installations, you already know this: sealants are often the first to give up when exposed to sun, heat, and moisture. Cracks show up. Edges pull away. Water sneaks in. And just like that, your clean, sealed finish becomes a source of complaints, repairs, and stress.

So how do you keep it from happening?

Let’s get into the real differences between UV-resistant elastomeric sealants, especially silicone-based options, and why they matter more than ever in modern construction.

What Happens to Sealants Under Constant UV Exposure?

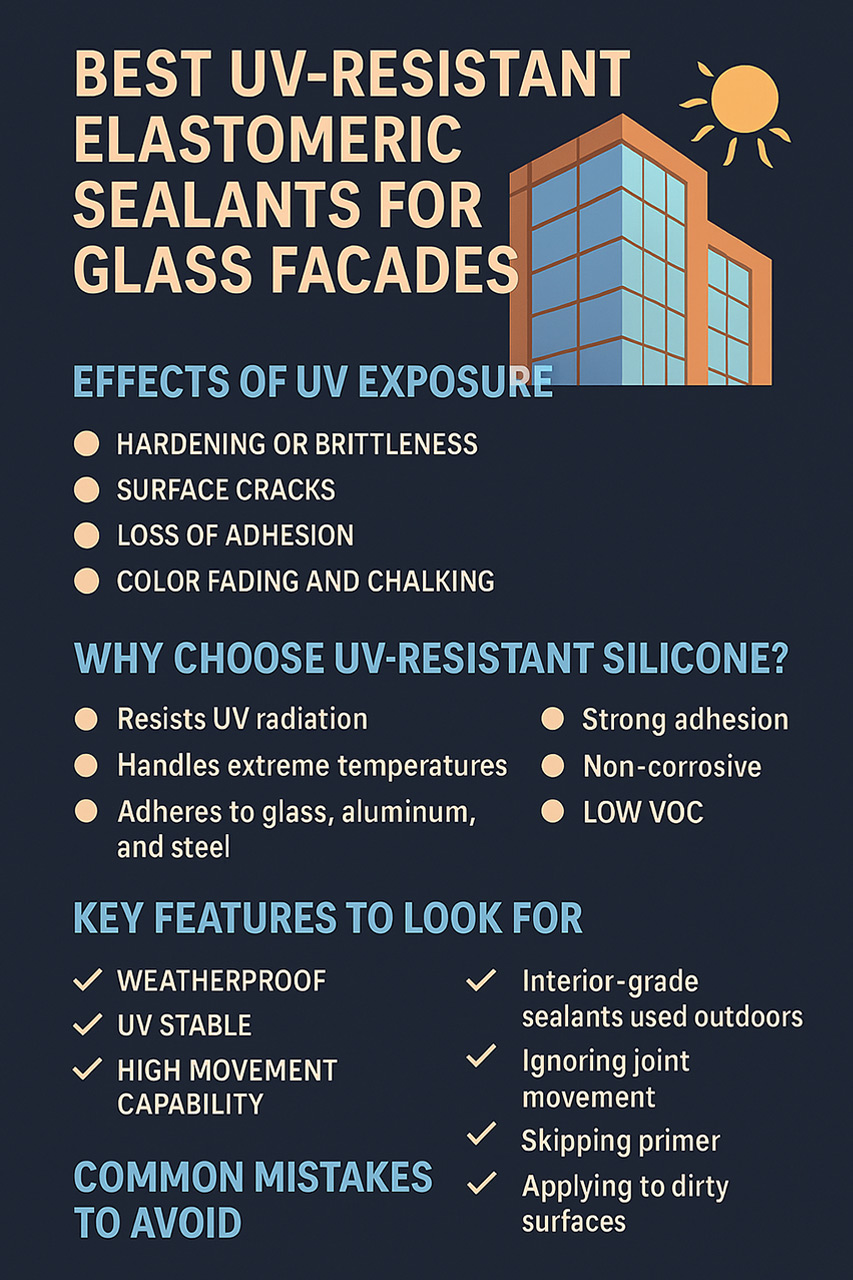

Rubber sealants are flexible by design. But UV light slowly breaks down the chemical bonds in those materials, leading to:

- Hardening or brittleness

- Surface cracks

- Loss of adhesion

- Color fading and chalking

- Shrinkage and movement failure

And this isn’t just about appearances. When sealants fail, water starts getting in, and that’s when things get expensive.

Common Sealant Types (And Why They React Differently to Sunlight)

Here’s a simple comparison:

| Sealant Type | UV Resistance | Typical Use | Downsides |

| Silicone (Neutral) | Excellent | Glass facades, curtain walls, windows | Slightly higher cost |

| Polyurethane | Moderate | Concrete joints, masonry, indoor use | Can yellow or degrade outside |

| Acrylic | Low | Gaps, cracks indoors | Not suitable for glass exteriors |

| Butyl Rubber | Moderate | Temporary fixes, lower-rise facades | Less durable under UV |

Bottom line? If you’re working on a high-rise, go with UV-resistant silicone. It stays flexible, doesn’t yellow, and holds up against extreme temperatures and UV exposure for years.

What Exactly Is UV-Resistant Elastomeric Sealant?

It’s a rubber-based sealing material designed to expand and contract with building movements without cracking or losing its grip, even when exposed to sunlight for 10–20 years.

Specifically, the “UV-resistant” part means:

- The sealant won’t break down from constant sun exposure

- It won’t lose flexibility or shrink

- It maintains its seal—keeping out air, water, and dust

Silicone-based elastomeric sealants are the top choice for this job. Why?

Because they:

- Resist UV radiation naturally (no stabilizers needed)

- Handle temperatures from -50°C to +200°C

- Stick to glass, aluminum, and steel—without primers in most cases

Real-World Example: What Happens When You Use the Wrong Sealant?

Let’s say you’re sealing glass panels on a luxury high-rise in Mumbai.

You choose a low-cost polyurethane sealant because it fits your budget. For the first six months, everything looks great. But then—summer hits. The sun beats down. The rubber starts shrinking. By monsoon season, complaints roll in. Water leaks. Edge separation. Expensive rework.

What seemed like a small cost-saving choice turns into a ₹12 lakh rectification job.

We’ve seen this story more than once.

Key Features to Look For in UV-Resistant Silicone Sealants

When shopping for the right sealant, focus on these attributes:

- Weatherproof: Performs under rain, humidity, heat, and cold

- UV Stable: Won’t yellow, crack, or break down

- High Movement Capability: +25% or more is ideal

- Strong Adhesion: Especially to glass, aluminum, and coated panels

- Non-Corrosive: Won’t damage metal or façade coatings

- Low VOC: Safer for the environment and workers

FAQs: What People Like You Are Asking

Which rubber sealants prevent UV damage in high-rise glass facades?

Neutral-cure silicone sealants are your best bet. They hold their shape, resist UV, and bond well with curtain wall components like glass, aluminum, and steel.

Why choose UV-resistant silicone for skyscrapers?

Because they handle extreme sun, wind, and temperature swings. On tall buildings, even small movements can stretch materials. Silicone stays flexible for decades—unlike cheaper alternatives that become brittle and fail.

Insider Tip: Not All Silicone Sealants Are the Same

Some silicone sealants are designed for indoor use or aesthetic finishes. They may not have the UV protection your façade needs.

Check for:

- ASTM C920 certification

- High modulus vs. low modulus (choose based on joint movement needs)

- Compatibility with your building materials

Also—don’t forget backer rods and primers. They matter just as much in creating long-term seal durability.

Cost vs. Lifetime Value

Yes, UV-resistant silicone sealants cost more upfront.

But here’s the truth:

- You spend a little more now

- You avoid massive repair costs later

- You get peace of mind for years

Here’s a quick comparison:

Below is a sample supplier performance scorecard:

| Metric | Generic PU Sealant | UV-Resistant Silicone |

| Price per kg (Approx) | ₹180–₹250 | ₹350–₹600 |

| Avg. Lifespan | 2–5 years | 15–20 years |

| Maintenance Needs | High | Minimal |

| Risk of Early Failure | High | Very Low |

Common Mistakes That Lead to UV Sealant Failure

- Choosing interior-grade sealants for exterior joints

- Not accounting for joint movement in design

- Applying sealant on dusty or damp surfaces

- Skipping primer (when required)

- Using expired or improperly stored products

Avoid these and you’ll extend the life of your façade—by a lot.

Key Takeaways

- UV exposure breaks down standard sealants quickly—especially in glass façade applications.

- Silicone-based elastomeric sealants are the top performers for long-term durability.

- Always check certifications, specs, and compatibility—not just price.

- Correct installation matters as much as product selection.

Final Thoughts

High-rise buildings come with high expectations—and even higher risks. Choosing the right sealant isn’t just a technical decision. It’s a business one.

Because when your seal fails, it’s your reputation that leaks first.

If you’re unsure about which product fits your project, or if you’d like samples of SEPL’s UV-tested EPDM and silicone sealants, our technical team is just a call away.

Ready to seal out the sun and seal in peace of mind?

Reach out to Team Saga for more such recommendations.