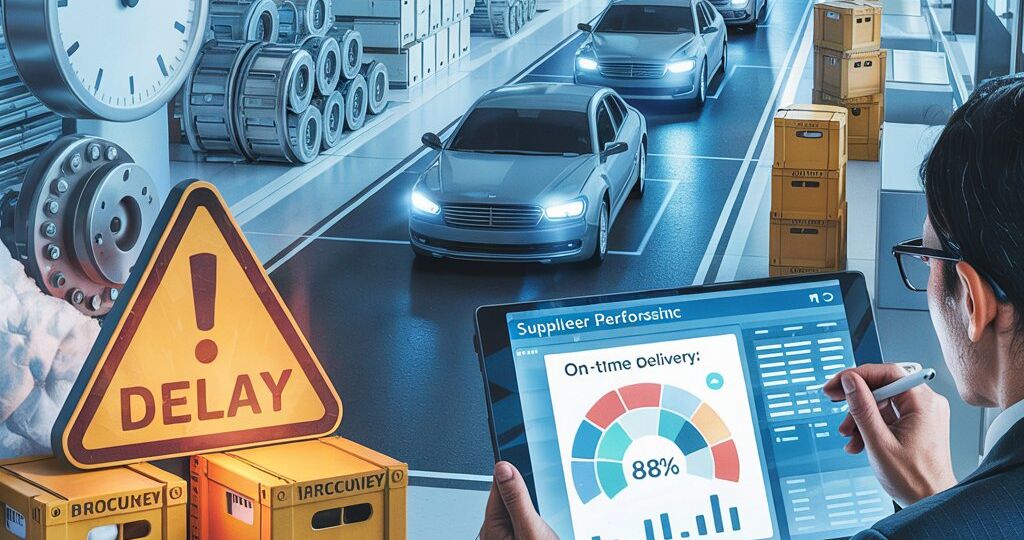

Learn why suppliers are late and improve performance with supplier scorecards and collaboration. Get actionable supply chain delay solutions now!

Knowledge Series

Explore how high-temperature resistant rubber for engines extends seal life and cuts maintenance, boosting engine performance.

TPE: Rubber-like flexibility with the processing ease of plastic. TPV: A more durable, cross-linked TPE ideal for harsh environments.

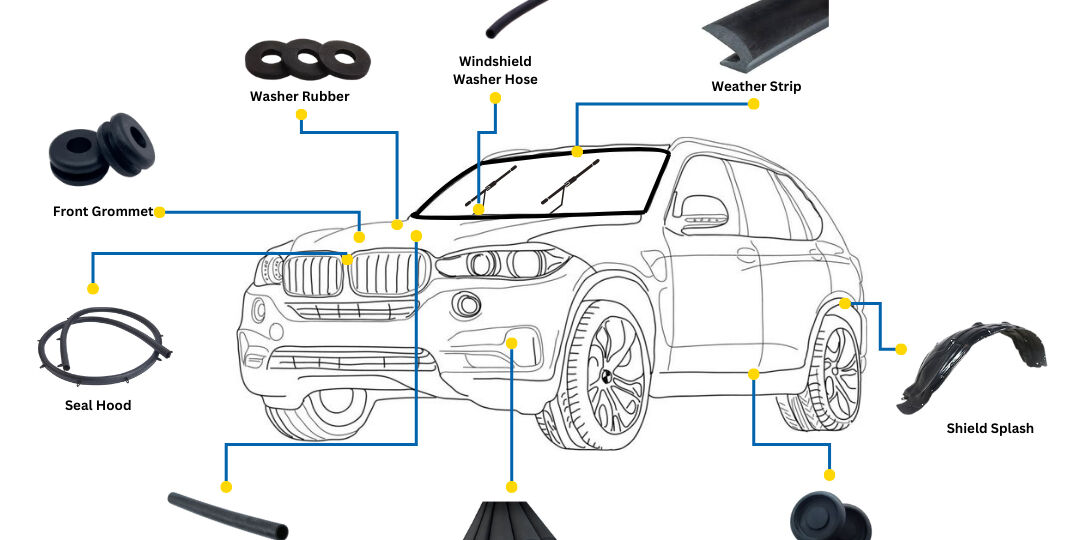

Discover how EPDM rubber improves vehicle durability, weather resistance, and performance. Learn EPDM’s key automotive applications here.

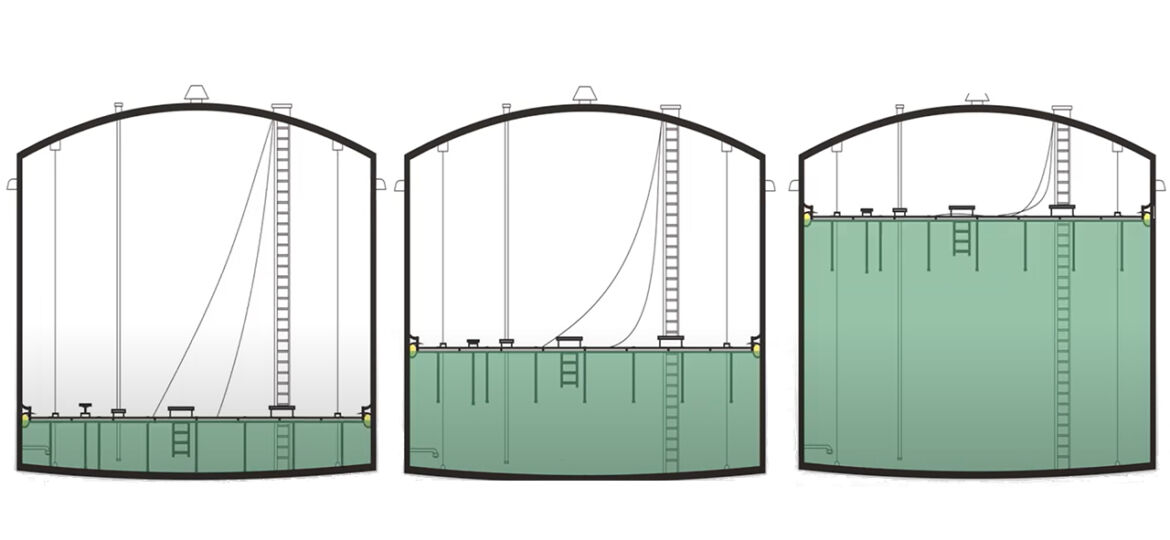

Why do some floating roof tanks outperform others?

The secret often lies in the abrasion resistance of their seals

Neoprene Vent Bands are used in most diversified mining applications like for heavy equipment housings, the enclosures of engines, and conveyor belts, ventilation vents. They make a snug seal keeping out dust, water, and other kinds of particles that may leak into the machinery and malfunction it.

Our advanced curtain glass profiles are designed to meet the highest standards of innovation and quality, ensuring your buildings not only look spectacular but also perform exceptionally well.

This article covers the importance of EPDM joint profiles, their benefits, and their use to ensure the ultimate level of safety and performance in road and bridge infrastructure.

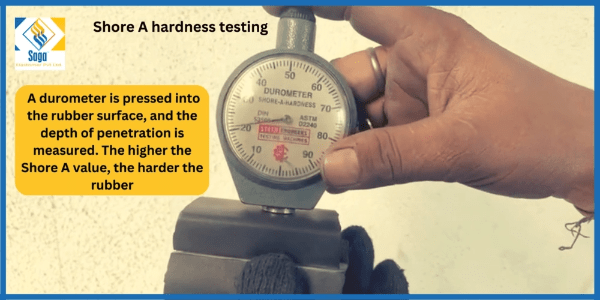

Learn how efficiently we can customize rubber compound hardness. Discover step-by-step processes and key considerations to meet your customer’s demands effectively.